Suzhou, Jiangsu Dec 11, 2025 (Issuewire.com) - The global manufacturing landscape is undergoing a significant transformation, driven by the demand for materials that can withstand increasingly harsh operating environments. At the core of this evolution are High Temperatures Plastic Partsadvanced polymer components engineered to maintain structural integrity, mechanical strength, and electrical properties under extreme thermal stress. These specialized parts are becoming indispensable across key industrial sectors, including aerospace, automotive, electronics, and precision machinery. As a leading player in this field, Suzhou Tiantai Chuangcai Innovative Material Technology Co.,Ltd is positioning itself as Chinas Best High Temperatures Plastic Parts Exporter, a reputation that will be strongly validated by its presence at the upcoming CHINA PLAS, the industrys most prestigious event.

Trends and Outlook: Tiantai's Role in a Growing Market

The global market for HTPs is experiencing robust growth, propelled by significant industrial trends toward lightweighting, miniaturization, and enhanced energy efficiency. Industries are rapidly substituting traditional materials, such as metals and ceramics, with HTPs to achieve superior performance characteristics under extreme conditions, including high heat, friction, and corrosive environments.

Tiantai's technological breakthrough directly positions us to meet and capitalize on this escalating demand. Our ability to supply machinable HTP components enables the rapid material substitution required by these global trends. This is particularly evident in regions like China, which has emerged as a powerhouse for advanced manufacturing and technological development. This enormous industrial base fuels an enormous demand for sophisticated, reliable polymer solutions, and Tiantais unique capability to deliver high-quality, easily processed HTPs secures our position at the forefront of this market's expansion, actively shaping the future of high-performance material applications.

The Strategic Importance of CHINA PLAS

For over four decades, CHINA PLAS has solidified its status as the premier trade fair for the plastics and rubber industries in Asia, and the second largest in the world. This UFI-approved event, which rotates between major hubs like Shanghai and Shenzhen, serves as a vital confluence where global supply meets escalating demand, offering an unparalleled platform for innovation and sourcing.

The exhibition typically draws an immense crowd, often exceeding 280,000 visitors, including a significant percentage of overseas professionals. Its record-breaking attendance figures are a clear testament to its role as a key indicator of industry health and future direction. Professionals from over 150 countries converge to witness live demonstrations, forge partnerships, and explore the complete value chainfrom raw materials and specialized chemicals to advanced machinery and end-use plastic parts.

For a company specializing in high-performance polymers, for example, Tiantai, the exhibition provides the ideal stage to:

More On Intelligenceninja ::

- Mitzi B Albo, Recognized by BestAgents.us as a 2025 Top Agent

- JIEZOU POWER: A China Best Solar Plant Transformer Manufacturer with ISO 9001 and CE Certifications

- Nohra Adams, PA-C, MPH: Championing Women’s Health with Expertise and Compassion

- Andrew (Drew) Zinkel, MD, MBA, Recognized as a Visionary Leader in Healthcare Innovation and Education

- China Best Baking Tray Manufacturer attended Bakery China

Showcase Technical Leadership: Tiantai's participation allows it to directly present its specialized productsincluding high-temperature gradesto a highly targeted audience of decision-makers and technical buyers.

Gauge Market Dynamics: The show is an essential venue for understanding the latest applications, competitor strategies, and evolving regulatory requirements, informing future R&D efforts.

Expand Global Reach: With a significant portion of visitors coming from outside China, CHINA PLAS is the most effective single point for an exporter like Tiantai to deepen its penetration into European, North American, and Southeast Asian markets.

By participating, Tiantai not only demonstrates its commitment to the global plastics community but also leverages the exhibitions influence to cement its reputation as a reliable and technologically capable high-temperature plastics manufacturer and exporter.

Tiantai's Core Advantage: Expertise, Innovation, and Customization

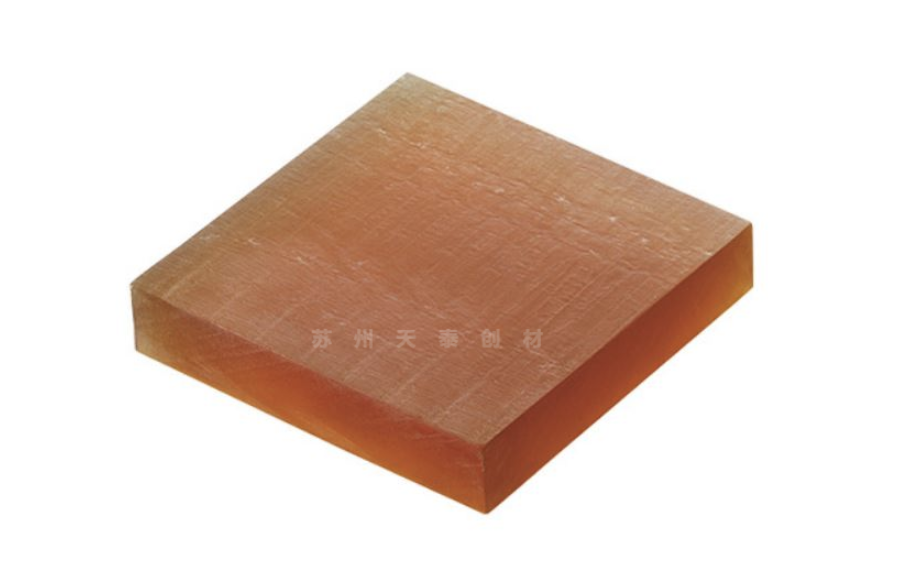

Suzhou Tiantai Chuangcai Innovative Material Technology Co., Ltd's market presence is not just a function of its geographic location; it is a direct result of its commitment to specialized technical research and development and its versatile manufacturing capability. The company is dedicated to advancing the state-of-the-art in engineering plastics, composite materials, and new materials, offering products in various forms, including sheets, rods, and tubes for machining.

Targeted Material Expertise and Application Focus

In addition to advanced processing, Tiantai demonstrates deep expertise in specific high-temperature materials and their niche applications:

Polyetherimide (PEI / ULTEM): Features high mechanical performance, excellent thermal and chemical stability, superior dimensional stability, and creep resistance. With a maximum continuous operating temperature of 170°C, it is widely applied in electrical insulation components, structural parts requiring high strength at temperature, and medical devices due to its hydrolytic resistance (autoclavable).

Polyvinylidene Fluoride (PVDF): Characterized by superb chemical resistance (to strong acids, etc.), excellent mechanical strength, and a wide service temperature range (between -40°C and +150°C). It is especially suited for pure water systems and the storage/transfer of pure chemical reagents in the semiconductor and chemical industries.

By pre-processing these challenging materials, Tiantai transforms them from difficult raw stock into reliable, ready-to-use intermediate forms, affirming our role not just as a material supplier but as a partner in manufacturing efficiency and innovation.

Technological Breakthrough: Shaping the Future with Machinable High-Performance Polymers

Tiantai is a recognized leader in navigating the historical challenges associated with processing High-Temperature Plastics (HTPs). Polymers such as PEEK, Polyimide, and PTFE are inherently difficult to fabricate due to their intrinsic rigidity, chemical inertness, and high melting pointsfactors that have traditionally limited their widespread adoption. However, Tiantai has achieved a substantial, industry-leading breakthrough that directly addresses this hurdle, allowing for the fusion of superior material performance with manufacturing efficiency.

Our core innovation lies in specializing in precision-engineered semi-finished High Temperatures Plastic Parts for machining. This capability is not merely about supply; it is a strategic technical focus that ensures end-users receive high-quality, stress-relieved plates, rods, and tubes. This crucial preparation enables these advanced materials to be easily and accurately machined into complex, final components, critically without sacrificing the intrinsic thermal, chemical, and mechanical properties of the base polymer.

Other Functional Material

Tiantais competitive edge is further defined by its expertise in formulating compounds that meet demanding thermal and functional specifications, providing enhanced properties in three critical functional areas:

Insulating materials with exceptional dielectric strength and volume resistivity, crucial for preventing electrical breakdown under high thermal stress. These materials are essential for the Electrical & Electronics (E&E) industry, ensuring the safety and longevity of electrical insulation systems in high-oltage motors, generators, and specialized electronic equipment where thermal stability and reliable electrical isolation are non-negotiable requirements.

Anti-static materials are designed to safely and quickly dissipate electrostatic charges. In sectors like semiconductor fabrication and precision instrument assembly, where static discharge can lead to catastrophic component damage or hazardous incidents, these materials are indispensable. By controlling surface resistivity, Tiantais anti-static polymers ensure product integrity and operational safety.

Conductive Material: For applications requiring stable electromagnetic interference (EMI) shielding or effective grounding, the company engineers highly reliable conductive materials. Through precise compounding and the incorporation of specialized fillers, these materials offer stable electrical conductivity while retaining the core mechanical and thermal properties of the engineering plastic matrix. This provides a lightweight, durable alternative to metal components in demanding EMI-sensitive or grounding applications.

Looking to the future

In an increasingly sophisticated global market, Tiantai Plastics combination of technical focus on challenging temperature plastic Parts, versatile product forms, and deep expertise in functional materials positions the company as a pivotal and reliable partner. Its prominent exhibition at CHINA PLAS serves as a declaration of its capability and readiness to support the next generation of advanced manufacturing worldwide.

For more information on Tiantais high-performance polymer products and technical specifications, please visit the company's official website: http://www.ttengineeringplastic.com

Media Contact

Suzhou Tiantai Chuangcai Innovative Material Technology Co.,Ltd

+86 17300622255

No.14 Factory Building,Yangshan Technology Industrial Park, No 8 Jinyan Road, High-tech District 215000 China Jiangsu Suzhou

Source :Suzhou Tiantai Chuangcai Innovative Material Technology Co.,Ltd.

This article was originally published by IssueWire. Read the original article here.