Xiamen, Fujian Dec 15, 2025 (Issuewire.com) - Metal fabrication is a cornerstone of modern manufacturing, transforming raw metal materials into functional structures, components, and products that power industries and everyday life. Tall buildings to even small automotive components are produced using the process of metal fabrication which involves cutting, bending, assembling and joining metal. It is an all-purpose craft that is a mix of precision, skill and hi-tech which is used to produce anything ranging between heavy and industrial machinery, and also to the sensitive consumer products such as cutlery. This article covers information about the complexity of metal fabrication, its operations, uses, and relevance in the modern world.

Understanding Metal Fabrication

Essentially, metal fabrication is a production process that entails the bending and assembly of metal into completed products or constructions. Raw materials, which may be sheet metal, plates, bars or welding wire, are manipulated using a variety of techniques in order to create the required form. Fabrication is also different from casting where molten metal is poured into molds and instead it mostly uses solid metal that is cut, bent or joined together to produce the final product.

The process of the raw material to the finished product begins with elaborate designs or shop drawings that in most cases are developed using the computer-aided design (CAD) software. Such designs are used as blueprints, which lead metalworkers in the making. These designs are then translated into real-life by skilled professionals i.e. welders, machinists, and ironworkers, with the combination of manual skill and state-of-the-art equipment. What has been produced is the large diversity of products, large-scale structural beam, and precision-engineered items used in the aerospace industry.

Vacuum Chamber Shell Being Produced by Openex

Key Processes in Metal Fabrication

There is a wide range of metal fabrication techniques but they are all dependent on the project requirements. The main processes are outlined below:

1. Cutting

More On Intelligenceninja ::

- Harrison Global Holdings Acquires ECRUX Venture Partners, Accelerating Global Investment Synergies

- Competitive Landscape Analysis: What Makes Jiansheng School Furniture Suppliers in China Stand Out

- Chief of Staff Association hosts two former White House chiefs of staff for expert discussion on leadership

- Christine Reiss, Recognized by BestAgents.us as a 2025 Top Agent

- Author Erin Banta Launches SHE RISES, a Bold Blueprint for Women to Reclaim Their Power

In most projects to do with fabrication, cutting is the initial stage where the raw metal is broken down into smaller and manageable fabrication work. Old techniques of sawing and shearing are not forgotten though the fabrication of the modern world is dependent on highly advanced technologies including:

- Laser Cutting: This process cuts metal with high intensity laser which is best suited in cutting up complicated designs.

- Plasma Cutting: It involves the use of ionized gas jet, which is used to cut through thick metal plates, this technique is mainly employed in heavy industries.

- Waterjet Cutting: This is where high-pressure water combined with abrasives are used to cut metal without heat generation and the integrity of the material remains.

These methods are accurate and efficient enough to enable fabricators to deal with metals of different thicknesses and compositions.

2. Bending and Forming

After being cut, metal is frequently bent or formed to the required geometry. This can be done using:

- Press Brakes: These are machinery that provide a certain amount of force to bend sheet metal to a specific angle.

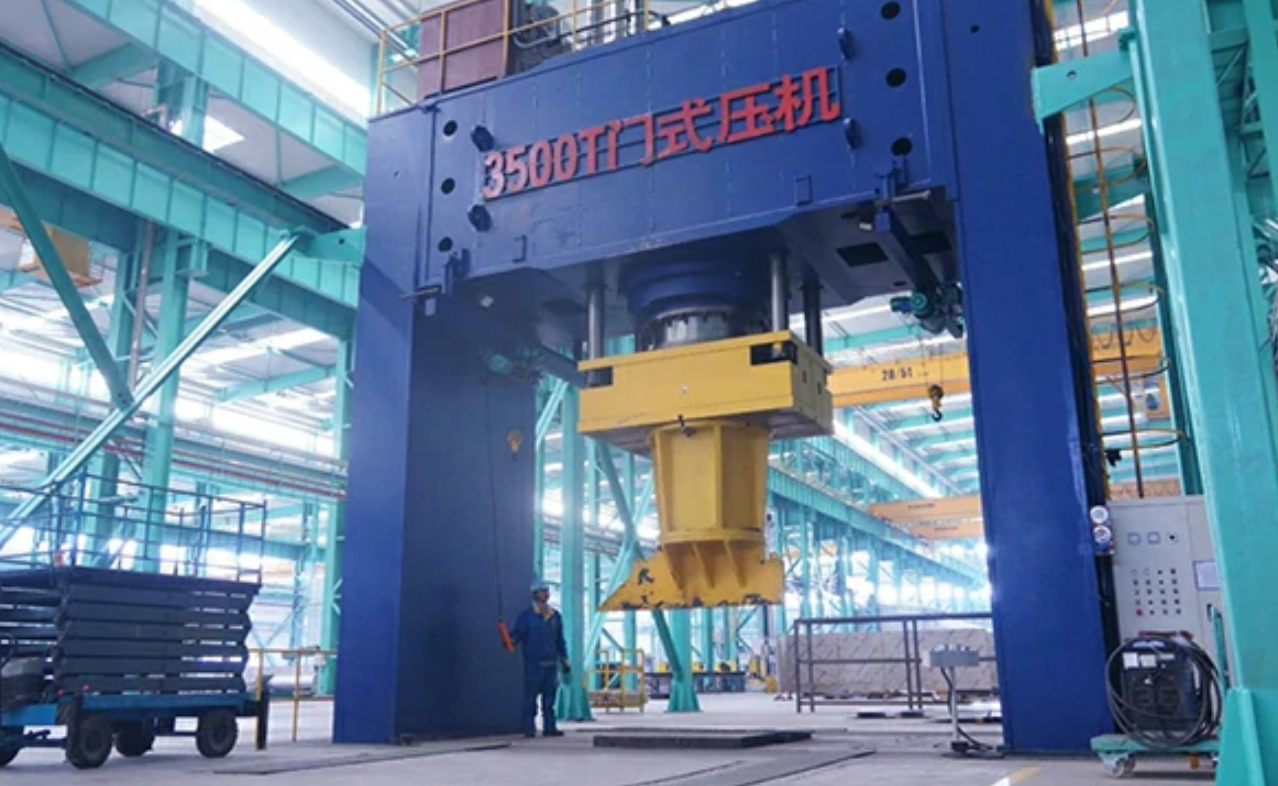

Openex has the capacity of press brake max 100mm in thickness and 18000mm in length.

- Roll Forming: This is a continuous process that materials are made into shaped profiles made of metal (long and uniform) that are used in roofing or structural beams.

Roll forming capacity Openex can use is over 200mm in thickness and 4200mm in width.

- Hydraulic Forming: This is a process where metal is pressed in a pair of diesto formed complex shapes gradually.

Hydraulic forming in Openex for metal parts of complex shape

Bending and forming must be calculated well to make sure that the metal does not lose its strength and structural integrity.

3. Assembling and Joining

The last fabrication process is to provide the cut and formed elements into a unified product. This is normally obtained by:

- Welding: It is a process in which metal segments are joined by heat to form very strong and permanent unions. The popular methods of welding are MIG, TIG, and arc welding.

- Fastening: Metal parts are attached using some mechanical means such as bolts, screws, or rivets, particularly when they need to be disassembled.

Openex even invested in developing Automated Optical Inspection machine to check the quality of the fasteners before assembling, no defects can escape the inspection of Openexs AOI machine

- Adhesive Bonding: Sometimes adhesive is used to attach metal parts especially in lightweight applications.

The joining methods have been selected according to the requirements of a project including strength, durability, or aesthetic.

Raw Materials in Metal Fabrication

Metal fabrication works with a large variety of materials and each one is chosen based on its specific properties. Common metals include:

- Steel: Steel is a popular product in building construction, automobile, and industries.

- Aluminum: Aluminum is light in weight and resistant to corrosion and is suitable in the aerospace and consumer products.

- Stainless Steel: The stainless steel is mostly utilized in the medical equipment and food processing due to its durability and resistance to rusting.

- Copper and Brass: Copper and Brass are very commonly utilized in decorative or electrical work, because they conduct and look nice.

The selection of the material will be based on materials such as strength, weight, resistance to corrosion and cost as well as the intended usage of the finished product.

Applications of Metal Fabrication

Metal fabrication is versatile and therefore is inevitable in many industries. There are some applications and these include:

- Construction: Fabrication manufactures structural elements such as beams, columns and trusses that are the structural backbone of construction and infrastructure.

- Automotive: Chassis, exhausts and its parts have precision parts made through fabrication that guarantee the performance and safety of a vehicle.

- Aerospace: Aircraft components require high precision manufacturing with lightweight materials and strict tolerances being the most important.

- Energy: Fabrication is helpful in the energy industry by manufacturing wind turbine parts, oil platforms and solar panels structure.

- Consumer Goods: All the things we use in our day-to-day life such as appliances, tools and cutlery are made up of fabrications to enhance their functionality and durability.

It is this broad applicability that makes metal fabrication such an essential factor in innovation and fulfilling the needs of the world in general.

The Place of Skilled Metalworkers.

The art of metal fabrication is more like an art than a science and complex processes involved in it require professional skills to carry out. The welders, machinists, and ironworkers contribute knowledge in all the fabrication processes, such as decoding the shop drawings, using sophisticated machines. To deliver quality outcomes, such professionals have to know metallurgy, accuracy, and safety measures. The training and certification helps to keep the metalworkers informed about the newest techniques and technologies and keep the industry of high standards.

The Role of Skilled Metalworkers

Metal fabrication is a science as well as an art that involves qualified professionals to conduct complicated tasks. The knowledge of the welders, machinists, and ironworkers is employed at all levels of the fabrication process, such as interpretation of shop drawings and use of sophsticated equipment. These experts should know metallurgy, accuracy, and safety measures to get the best outcomes. It is also possible to sustain the high standards of the industry by training and certifying the metalworkers to keep them informed about the new methods and technologies.

The innovation of Metal Fabrication.

Metal fabrication has also gained many developments with the technological improvement. Robotics and automation have simplified operations making them efficient and error-free. Precise cutting and shaping can be done using computer numerical control (CNC) machines, and 3D printing is also developing as a complementary technology to prototyping and small-scale production. Besides, sustainable operations, including scrap metal recycling and consumption of less energy consuming machinery are now becoming part of the present-day fabrication, which is in line with the international environmental agenda.

Difficulties In Metal Fabrication

With all its improvements, metal fabrication is challenged. The industry is also labor and equipment intensive, and therefore it may be expensive. Also, changing the price of raw materials and supply chain failures may influence the production schedule. Fabricators also have to overcome rigid rules and quality requirements especially in such areas as aerospace and medical production. It is possible to overcome all these challenges only through innovation, flexibility, and commitment to excellence.

Future of Metal Fabrication.

With the continued changes in industries, metal fabrication will be critical towards supporting emerging requirements. Smart manufacturing, which is coming up due to the Internet of Things (IoT) and artificial intelligence, will enable better productivity and personalization in production. Also, the current focus on lightweight and sustainable developments will influence the future of fabrication making it a crucial component of global production.

The process of metal fabrication is dynamic and critical and it converts raw metal into the structures and products that characterize contemporary life. With the help of cutting, bending, assembling, and joining, all the things, including the tallest skyscrapers and the tiny parts with an exceptionally high level of accuracy, are made by the skilled metalworkers. With the current technological growth and changing industries, metal fabrication keeps up with the times, leading to innovation and satisfaction of the ever-changing world. In the construction industry, aerospace industry and consumer goods, the role of metal fabrication cannot be underestimated, and thus it is a foundation of the contemporary manufacturing industry.

Ready to bring your metal fabrication project to life or your business? Openex deals with fabricated metal safety products and steel welding solutions of high quality, which are customized to match mining, oil and gas, automobiles, and aerospace sectors among others. Using the best possible equipment and experience, Openex has the potential to take your design prototype to production and finish it with perfection and efficiency. To know more and begin working on your project now, visit: https://www.cncmetalworking.com/

Media Contact

Openex

+86 186 5928 0806

No. 99 Yilan Rd., Xiamen , CN.

Source :Openex

This article was originally published by IssueWire. Read the original article here.

11 day's ago